![]() High environmental standards

High environmental standards

![]() Persist in meticulousness

Persist in meticulousness

advantage Durable and sturdy, with low energy consumption

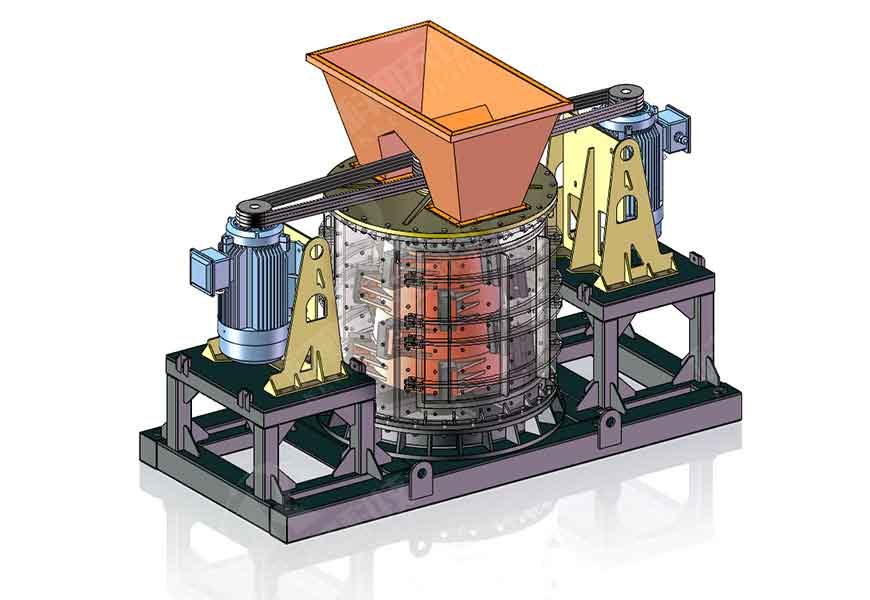

The vertical plate hammer number control sand machine is a kind of adjustable fine crushing sand making equipment without screen bar, which is optimized and designed on the basis of absorbing the domestic vertical shaft impact sand making machine equipment. It can be widely applied to the raw material and clinker fine crushing operation in railway, highway and airport. At the same time can also be used for dolomite, coke gem, lead zinc ore, serpentine, blast furnace slag, coal gangue, phosphate ore and other medium hardness materials of fine crushing sand operation, so the vertical plate hammer number control sand machine is especially suitable for hard limestone, dolomite, granite, basalt and other artificial sand or highway pavement stone processing and crushing.

Simple operation, high flexibility, the use of centralized frequency conversion electronic control system to operate the equipment, can achieve one-button start, reduce the cost of equipment labor.

The finished product has good grain shape, no cracks under the microscope of the finished sand, meets the national high standard demand for sand, reasonable grading, high yield, compared with other traditional sand making equipment, its output can be increased by 30%.

Low consumption of wearing parts, cone crushing chamber is designed according to the material impact Angle, to ensure the high efficiency and stability of the digital control sand machine.

Plate hammer liner wear small, convenient maintenance, no screen bottom does not block material, a molding.

Material from the hopper into the number of control sand machine crushing chamber and installed on the inner wall of the counter plate violent collision, crushing or produce a large number of hair cracks, then the material into the conical rotor cavity, in the conical space is spirally down, by punching, extrusion, so that the cracked ore is further broken. The speed of the inner rotor of the sand machine is controlled by the intelligent program to achieve the corresponding crushing effect.

| specification model | Cylinder diameter( inch) | production capacity(t/h) | Feed size(mm) | discharging granularity(mm) | rate of finished products( percentage) | motor power(kw) | Variable frequency CNC cabinet(kw) |

| HYZS-29 | 29 | 10-20 | <50 | 3mm The following adjustable | 60-95% | 37-45 | 50 |

| HYZS-39 | 39 | 20-40 | <65 | 3mm The following adjustable | 60-95% | 55-75 | 90 |

| HYZS-49 | 49 | 30-60 | <70 | 3mm The following adjustable | 60-95% | 90-110 | 160 |

| HYZS-59 | 59 | 50-100 | <85 | 3mm The following adjustable | 60-95% | 132-160 | 200 |

| HYZS-69 | 69 | 80-160 | <100 | 3mm The following adjustable | 60-95% | 220-250 | 210 |

| HYZS-79 | 79 | 120-240 | <120 | 3mm The following adjustable | 60-95% | 132*2 | 280 |