![]() High environmental standards

High environmental standards

![]() Persist in meticulousness

Persist in meticulousness

advantage Durable and sturdy, with low energy consumption

Applicable materials:All kinds of rocks, ores, limestone, etc.

Jaw crusher is suitable for metallurgy, mining, construction and railway departments, as the initial crushing, crushing compressive strength of all kinds of ore or rock below 250MPa, has the characteristics of large crushing ratio, uniform particle size of finished products, low power consumption, simple structure, reliable work, easy maintenance, low operating costs, easy maintenance and so on.

The structure of the front plate is optimized, so that the crushing chamber is deepened and there is no dead zone, the material is broken more times, the stroke of the moving jaw is increased, the material is discharged smoothly, and the crushing capacity is also improved.

Gasket type discharge port adjustment device, reliable and convenient, large adjustment range, increase the flexibility of the equipment.

It is made of high strength manganese steel and cast in one molding. It has the characteristics of wear resistance, compression resistance and long service life.

Simple structure, reliable operation, low operating costs, safe and reliable lubrication system, easy parts replacement.

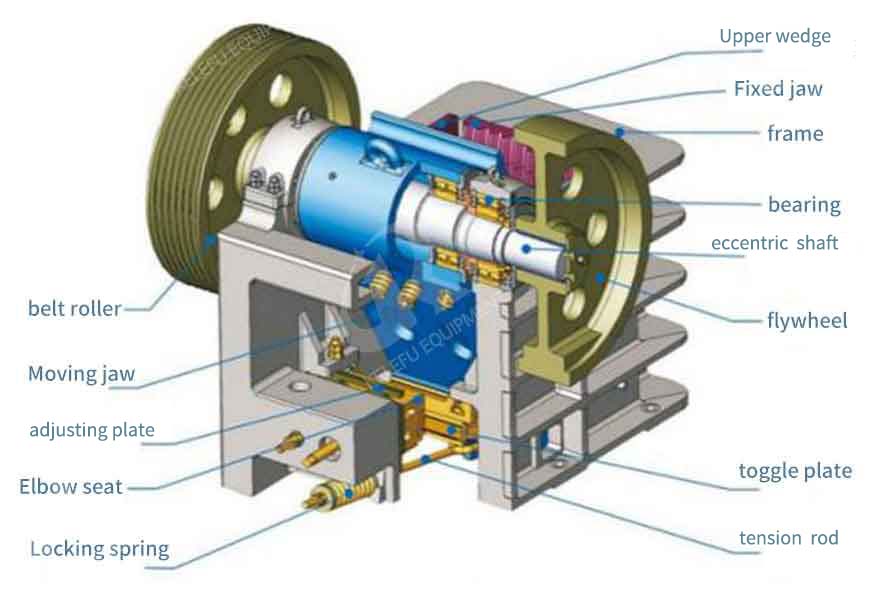

Jaw crusher commonly known as jaw broken, by the dynamic jaw and static jaw two jaw plate composed of crushing chamber, simulate the animal's two jaw movement and complete the crushing operation of the crusher. The working part of the jaw crusher is two jaw plates. When the jaw crusher is working, the movable jaw plate makes periodic reciprocating motion to the fixed jaw plate. When it is close to the jaw plate, the material is squeezed, split and impacted between the two jaw plates. When leaving, the broken material is discharged from the discharge port by gravity.

| model | Feed port size (mm) | Maximum feed(mm) | Discharge port adjustment range | handling capacity (t/h) | rate of work (kw) |

| PE150×250 | 150×250 | 125 | 10-40 | 1-5 | 5.5 |

| PE250×450 | 250×450 | 210 | 20-60 | 5-21 | 15 |

| PE250×1000 | 250×1000 | 210 | 25-60 | 15-52 | 30 |

| PE250×1200 | 250×1200 | 210 | 25-60 | 20-60 | 37 |

| PE300×1300 | 300×1300 | 260 | 30-90 | 30-870 | 55 |

| PE400×600 | 400×600 | 340 | 40-100 | 16-65 | 30 |

| PE500×750 | 500×750 | 425 | 50-100 | 50-100 | 55 |

| PE600×900 | 600×900 | 500 | 65-160 | 50-120 | 55-75 |

| PE750×1060 | 750×1060 | 630 | 80-18 | 52-180 | 110-132 |

| PE800×1060 | 800×1060 | 640 | 100-200 | 136-230 | 110-132 |

| PE900×1200 | 900×1200 | 750 | 100-210 | 150-320 | 110-132 |

| PE1000×1200 | 1000×1200 | 850 | 195-265 | 280-360 | 110-132 |

| PE1200×1500 | 1200×1500 | 1020 | 150-300 | 400-800 | 160-180 |