![]() High environmental standards

High environmental standards

![]() Persist in meticulousness

Persist in meticulousness

advantage Durable and sturdy, with low energy consumption

Applicable materials:The compressive degree is not more than 300Mpa, surface moisture is not more than 8%-10% of the ore, rock.

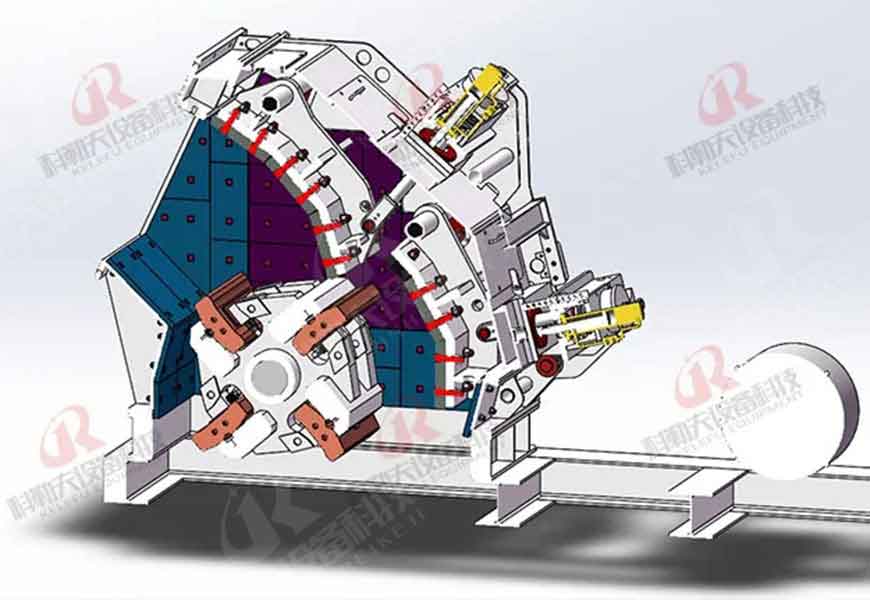

Heavy-duty high-efficiency large-caliber impact crusher is a new generation of impact crusher developed on the basis of traditional impact crusher combined with the specific mining conditions of sand and gravel industry. Compared with traditional impact crusher, it can not only ensure the advantages of impact granulation-breaking type, but also greatly improve the crushing ratio and output. It is mainly used in water and electricity, highway, building materials waste treatment and artificial construction aggregate processing.

Hydraulic automatic adjustment of the counter frame and the gap between the plate hammer, convenient, fast.

Using the special heavy rotor design principle, has greater rotation inertia, improve the crushing efficiency, and has the effect of energy saving.

Using hydraulic lifting and maintenance lifting device, can quickly complete the plate hammer and other wearing parts replacement, reduce downtime and equipment maintenance time, reduce maintenance costs.

Bearing seat adopts the principle of integrated design, the interior adopts multi-stage sealing, dustproof and waterproof effect is good; The interior lining board adopts modular design, which makes the wearing parts play a large use efficiency.

A crushing machine that uses impact energy to break materials. When working, the motor drives the rotor to rotate at high speed. When the material enters the plate hammer, it is broken by the high speed impact of the plate hammer. The broken material is thrown to the counter plate installed above the rotor along the tangential direction and broken again, and then springs back from the counter plate to the plate hammer action area and broken again. This process is repeated until the material is broken to the desired size and discharged through the discharge port. Adjusting the clearance between the counter frame and the rotor can achieve the purpose of changing the size and shape of the material.

| specification/ project | Rotor size(mm) | Maximum feed size (mm) | Discharge size(mm) | production capacity(m3/h) | installed power(kw) | |

| -150Mpa | -250Mpa | |||||

| PFQ0808 | ф850×750 | 200 | 150 | 25(80-90%) | 40 | -55 |

| PFQ1108 | ф1040×750 | 300 | 180 | 30(80-90%) | 95 | -90 |

| PFQ1110 | ф1040×1000 | 400 | 200 | 35(80-90%) | 110 | -110 |

| PFQ1310 | ф1280×1000 | 500 | 250 | 40(80-90%) | 175 | -160 |

| PFQ1313 | ф1280×1250 | 600 | 250 | 40(80-90%) | 220 | -220 |

| PFQ1315 | ф1280×1500 | 700 | 300 | 50(80-90%) | 285 | -300 |

| PFQ1515 | ф1450×1500 | 1000 | 350 | 50(80-90%) | 400 | -400 |

| PFQ1520 | ф1450×2000 | 1000 | 400 | 50(80-90%) | 540 | -550 |