![]() High environmental standards

High environmental standards

![]() Persist in meticulousness

Persist in meticulousness

advantage Durable and sturdy, with low energy consumption

Applicable materials:Widely used in all kinds of stone crushing, such as marble, granite, pebble, iron ore, feldspar and so on.

According to the different working principle, there are more types of equipment. At present, the most popular models are: full hydraulic type, multi-cylinder hydraulic type, compound type, single cylinder cone crusher and mobile cone crusher. The equipment has excellent performance and complete models, which can be used in various large, medium and small stone production lines to meet the production needs of users with different capacity.

Three-dimensional structure design, small footprint, the use of advanced technology, high degree of intelligence, simple operation and maintenance.

Low operating cost, less energy consumption per unit, large crushing ratio, good crushing effect.

Can effectively ensure the crushing process of low noise, zero pollution, for the operator to create a healthy operating environment, in line with environmental standards.

Choose more hard material, has the characteristics of durability, long service life, in general, cone broken is a good choice for crushing.

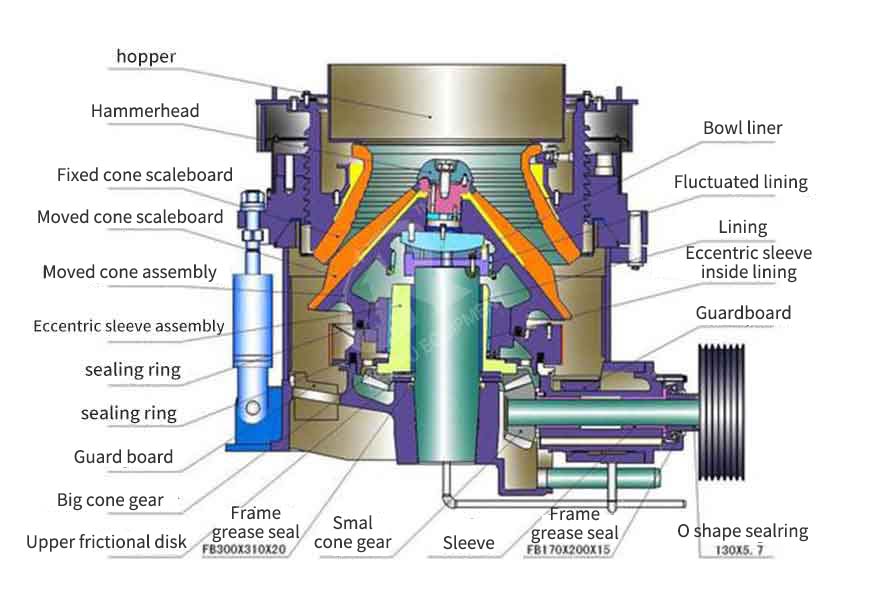

When working, the motor drives the drive shaft of the machine through the pulley or coupling, and the cone of the machine moves around the fixed point under the force of the eccentric sleeve. So that the broken wall of the crushing cone is sometimes close to and sometimes leave the surface of the rolling mortar wall fixed on the adjusting sleeve, so that the ore is constantly impacted in the crushing chamber, extrusion and bending action to achieve the crushing of the ore. The motor drives the eccentric sleeve to rotate through the bevel gear and makes the crushing cone swing. The crushing cone sometimes approaches and sometimes leaves the fixed cone to complete the crushing and discharging.

| model | Moving cone diameter (mm) | Cavity type | Feeding port size (mm) | Size of discharge port (mm) | Capacity (t/h) | motor power (kw) | Main engine weight (t) |

| HPC-200 | 950 | C | 150 | 13 | 120-240 | 160 | 13 |

| F | 76 | 6 | 55-180 | ||||

| HPC-300 | 1160 | C | 225 | 13 | 150-430 | 220 | 19 |

| F | 86 | 6 | 90-260 | ||||

| HPC-400 | 1400 | C | 290 | 13 | 190-610 | 315 | 26 |

| F | 100 | 6 | 108-320 | ||||

| HPC-500 | 1500 | C | 320 | 13 | 230-700 | 400 | 33 |

| F | 110 | 6 | 145-430 | ||||