![]() High environmental standards

High environmental standards

![]() Persist in meticulousness

Persist in meticulousness

advantage Durable and sturdy, with low energy consumption

it is widely used in metallurgy, building, hydropower, transportation, chemical industry

Hydraulic protection and hydraulic cavity cleaning, high degree of automation, reduce downtime

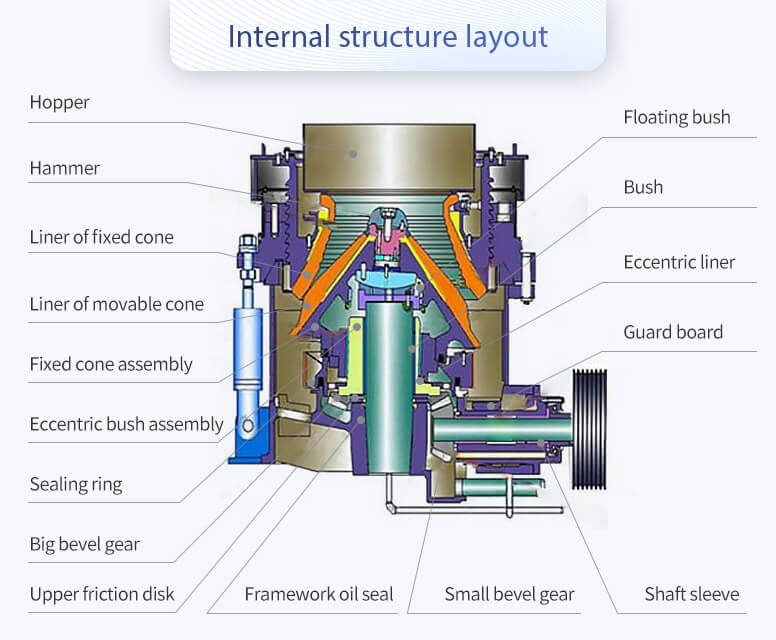

When hydraulic cone crusher begins to work, the electro motor drives the eccentric sleeve through the spring coupling, drive shaft and a pair of angle gear, so that the crushing wall of cone crusher gets close to and then gets away from the surface of the rolling mortar wall fixed on the adjusting sleeve, and the ores inside the crushing chamber will be constantly impacted, squeezed and bent to be crushed.

Model NO. | Type of Cavity | Output Size (mm) | Max. Feeding Size (mm) | Capacity (t/h) | Motor Power (kw) | Moving cone Diemeter (mm) |

HPY200 | C | 13 | 150 | 120-240 | 160 | 950 |

F | 6 | 76 | 55-180 | 160 | 950 | |

HPY300 | C | 13 | 225 | 150-430 | 220 | 1160 |

F | 6 | 86 | 90-260 | 220 | 1160 | |

HPY400 | C | 13 | 290 | 190-610 | 315 | 1400 |

F | 6 | 100 | 108-320 | 315 | 1400 | |

HPY500 | C | 13 | 320 | 230-700 | 400 | 1500 |

F | 6 | 110 | 145-430 | 400 | 1500 | |

HPY600 | C | 13 | 350 | 325-1150 | 630 | 1800 |

F | 8 | 120 | 245-730 | 630 | 1800 |