![]() High environmental standards

High environmental standards

![]() Persist in meticulousness

Persist in meticulousness

advantage Durable and sturdy, with low energy consumption

Applicable materials:Coal, salt, white, gypsum, alum, brick, limestone, etc.

Heavy hammer crusher is the use of high-speed rotary hammer impact ore, so that the ore along its natural cracks, in bed and joint surface and other fragile parts. Generally, hammer crusher with heavy hammer head, small number of hammer, slow speed, with upper grate and hammer disk structure can enter large particle size materials, should be used as medium crushing or a certain range of coarse crushing.

The crushing equipment has a high degree of automation, and the crushing ratio is large. After crushing, the products are cube shaped, with low content of needles and sheets, no internal cracks, high compressive strength, good particle shape and high yield of finished products.

Low investment is high yield. The wearing parts of the equipment are made of domestic raw materials with strong compressive resistance and wear-resistant, with small loss and long service life, which can reduce the input cost and bring considerable economic benefits to customers.

After several improvements and optimization of the equipment, the structure design is more reasonable, the operation is more convenient, the use cycle of parts is long, the user in the equipment maintenance and parts replacement of the total cost is lower.

The finished material can be adjusted according to the demand. The coarse, medium and fine specifications are complete. The broken product has no sheet, no smooth body, and the multi-angle and multi-edge guarantee the compressive strength.

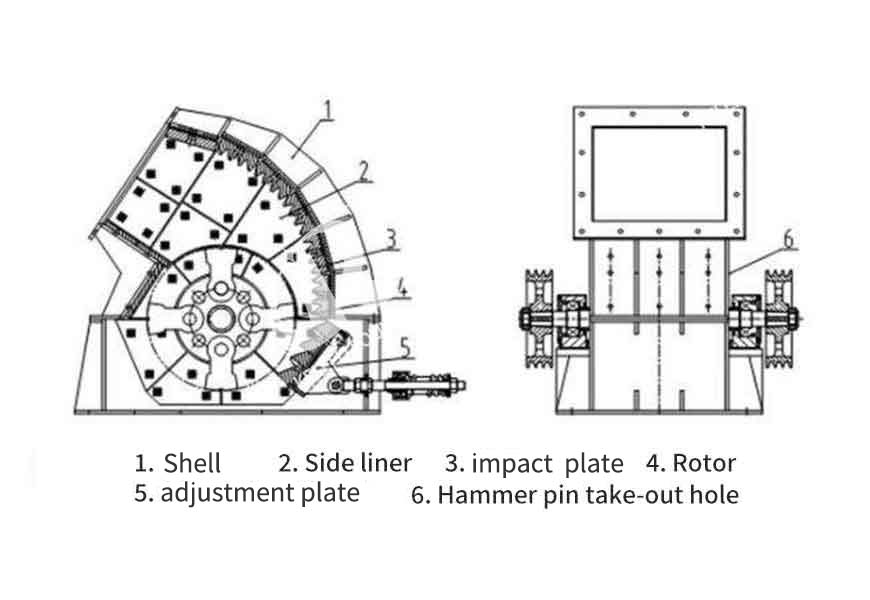

The main working part of this machine is the rotor with a hammer (also known as the hammer head). The rotor consists of a spindle, a disc, a pin shaft and a hammer. The motor drives the rotor to rotate at high speed in the crushing chamber. The material is fed into the machine from the upper feeding port, and crushed by the hammer of high-speed movement, impact, shear and grinding. In the lower part of the rotor, is provided with a screen plate, crushed material smaller than the size of the sieve through the sieve plate discharge, larger than the size of the sieve size of the coarse grained resistance to remain in the sieve plate continue to be hit by the hammer and grinding, finally through the sieve plate discharge machine.

| model | Feed port size (mm) | Feed size (mm) | production capacity(t/h) | rate of work (kw) |

| PCZ1308 | 850×800 | ≤600 | 100-160 | 132 |

| PCZ1510 | 1000×900 | ≤700 | 160-210 | 132×2 |

| PCZ1512 | 1200×900 | ≤750 | 250-320 | 160×2 |

| PCZ1615 | 1500×1200 | ≤1000 | 420-500 | 200×2 |

| PCZ1620 | 2000×1200 | ≤1200 | 800-1000 | 400×2 |

| PCZ1820 | 2000×1200 | ≤1200 | 1000-1200 | 450×2 |

| PC0706 | 618×510 | ≤400 | 50-70 | 75 |

| PC0808 | 780×610 | ≤500 | 80-100 | 132 |

| PC0910 | 1070×750 | ≤600 | 150-200 | 110×2 |

| PC1012 | 1255×810 | ≤650 | 250-300 | 132×2 |

| PC1213 | 1350×920 | ≤750 | 300-350 | 160×2 |

| PC1216 | 1530×920 | ≤750 | 400-500 | 200×2 |

| PC1220 | 2000×920 | ≤750 | 500-600 | 220×2 |