![]() High environmental standards

High environmental standards

![]() Persist in meticulousness

Persist in meticulousness

advantage Durable and sturdy, with low energy consumption

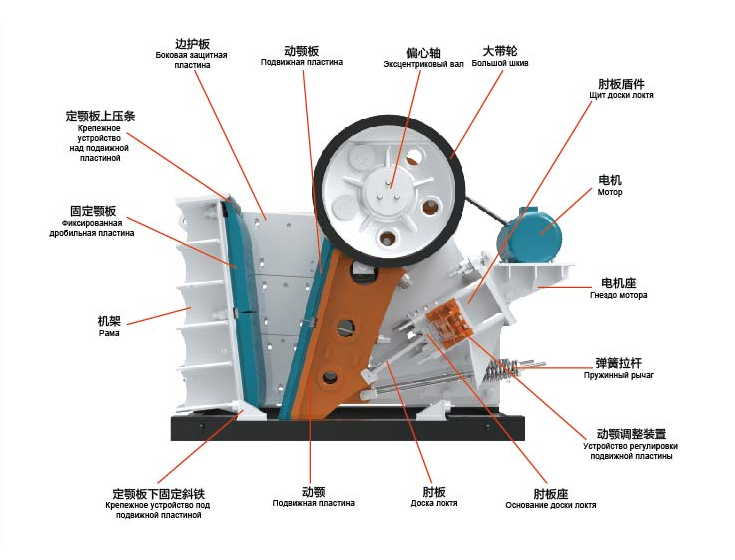

European jaw crusher is mainly applicable materials Limestone, calcite, granite, basalt, river pebbles, slag, slag, marble, gypsum and other mines and rocks.

Its working principle is that the motor drives the belt and pulley to swing the moving jaw up and down through the eccentric shaft. When the moving jaw pushes the moving jaw plate to move to the fixed jaw plate, the materials are crushed or chopped. When the movable jaw and the movable jaw plate retreat under the action of eccentric shaft and spring, the previously crushed or chopped materials are discharged from the lower discharge port of the jaw plate. With the continuous rotation of the motor, the crusher can crush and discharge materials periodically to realize mass production

Feeding port size(mm) | Max feed size(mm) | Outlet adjustment range(mm) | Production(t/h) | Motor power(kw) | |

klf65 | 450*65 | 380 | 40-100 | 35-120 | 45 |

klf80 | 550*800 | 460 | 70-150 | 100-220 | 55 |

klf95 | 650*950 | 550 | 80-160 | 150-280 | 75 |

klf110 | 800*1100 | 680 | 120-200 | 250-500 | 110 |

klf120 | 950*1200 | 820 | 140-220 | 350-650 | 160 |

klf130 | 1100*1300 | 950 | 160-280 | 400-800 | 185 |

klf145 | 1100*1450 | 950 | 160-280 | 420-900 | 200 |

klf150 | 1300*1500 | 1100 | 180-300 | 550-950 | 220 |

klf180 | 1500*1800 | 1300 | 200-320 | 800-1200 | 335 |